Choosing the right color changing cup manufacturer is one of the most critical decisions for brands, wholesalers, and promotional companies.

A reliable factory ensures:

Stable color changing performance

Consistent quality

Compliance with regulations

Lower long-term risk

As a professional color changing cup manufacturer, this guide explains how buyers should evaluate factories, what really matters behind the scenes, and how to avoid common sourcing mistakes.

1. Why Manufacturer Selection Matters

Color changing cups are not ordinary drinkware.

They combine:

Functional thermochromic technology

Surface coating processes

Food-contact safety requirements

A factory without experience can easily cause:

Inconsistent color change

Premature fading

After-sales complaints

2. Core Capabilities a Professional Manufacturer Should Have

In-House Color Changing Technology Knowledge

A qualified factory understands:

Thermochromic ink behavior

Activation temperature control

Ink–material compatibility

Without this, suppliers rely on trial-and-error.

Multiple Material Production Experience

A strong manufacturer can handle:

Plastic color changing tumblers

This allows them to recommend the right material, not just the cheapest one.

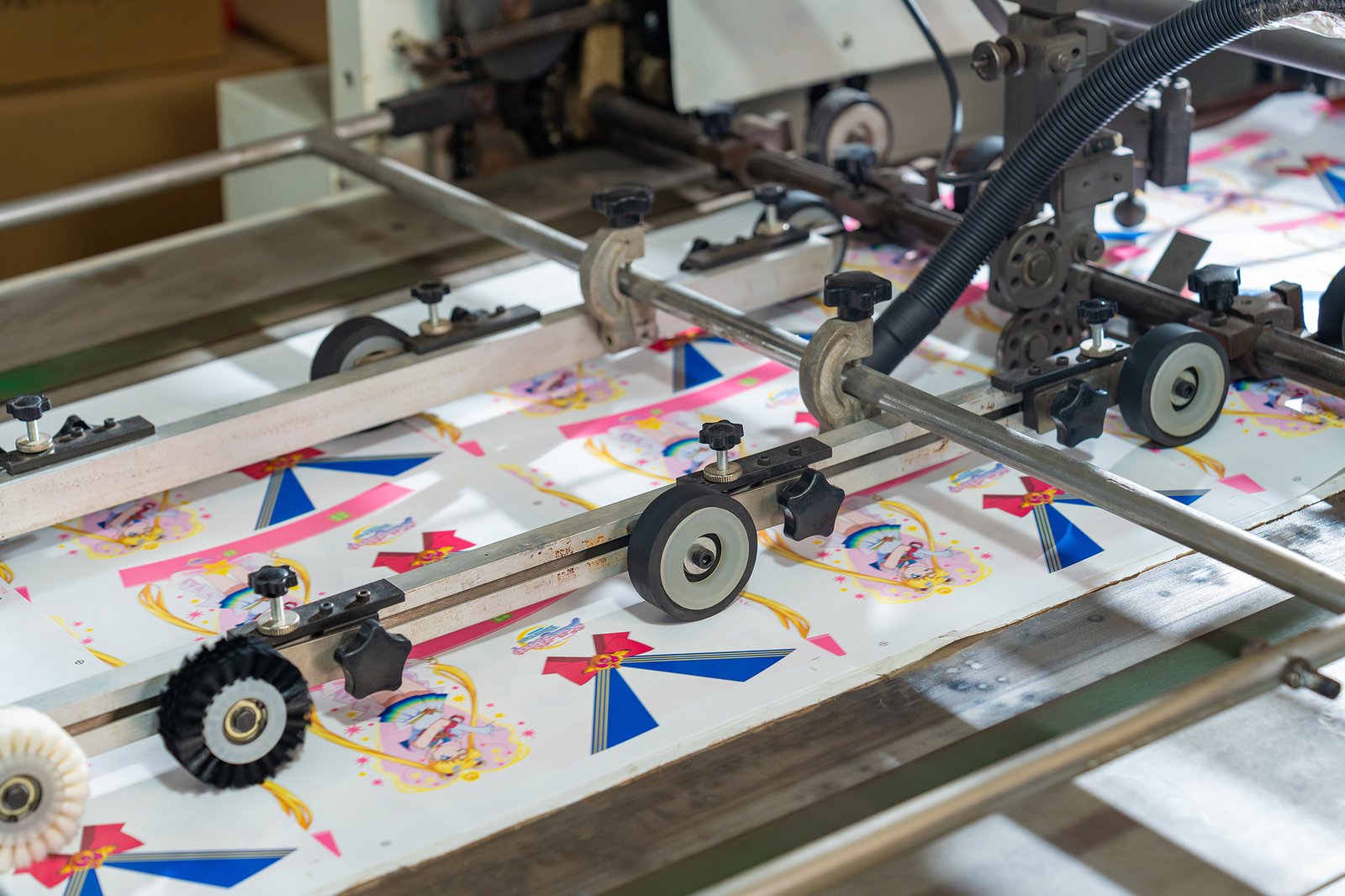

3. OEM & Customization Capabilities

For B2B buyers, OEM ability is essential.

A reliable manufacturer should support:

Custom colors & designs

Logo printing and decoration

Activation temperature selection

Private label packaging

Limited OEM options often indicate limited technical depth.

4. Quality Control & Consistency

Professional factories implement:

Incoming material inspection

Process-level quality checks

Finished product testing

Key quality points include:

Color change clarity

Color recovery speed

Adhesion and abrasion resistance

Consistency across batches is more important than samples.

5. Safety & Compliance Standards

A professional manufacturer clearly separates:

Inner food-contact material

Outer color changing layer

They should be familiar with:

FDA requirements (USA)

LFGB / EU food-contact standards

Compliance knowledge reduces risk for global brands.

6. Durability Testing & Lifespan Control

Experienced factories conduct:

Heat cycle testing

Washing resistance evaluation

Visual contrast monitoring

Instead of claiming “never fade,”

a reliable manufacturer explains expected lifespan honestly.

7. Common Red Flags When Choosing a Factory

B2B buyers should be cautious if a supplier:

Cannot explain fading causes

Promises permanent color change

Avoids technical questions

Offers unusually low pricing

These often lead to long-term quality issues.

8. How MOQ, Price & Lead Time Reflect Factory Level

| Factor | Professional Factory | Low-End Supplier |

|---|---|---|

| MOQ | Reasonable | Unrealistically low |

| Price | Market-aligned | Too cheap |

| Lead Time | Predictable | Unstable |

| Communication | Technical | Sales-only |

9. How to Communicate with a Manufacturer Effectively

To get accurate quotes and solutions, buyers should provide:

Target market

Usage scenario

Expected lifespan

Certification requirements

Clear input leads to better product outcomes.

10. Manufacturer vs Trader: What’s the Difference?

A true manufacturer:

Controls production

Understands ink and coating

Manages quality internally

A trader:

Relies on third-party factories

Has limited technical control

Cannot solve production-level issues

For OEM projects, factory-direct sourcing reduces risk.

11. What a Professional Manufacturer Will Recommend

Instead of selling aggressively, a good factory will:

Suggest realistic activation temperatures

Explain material trade-offs

Set proper usage expectations

This approach protects both parties.

12. Final Advice from the Manufacturer

The best color changing cup manufacturer is not the cheapest one, but the one who understands technology, quality, and long-term performance.

Choosing the right partner leads to:

Fewer complaints

Better customer experience

Stronger brand reputation

Looking for a Reliable Color Changing Cup Manufacturer?

If you are sourcing:

Private label drinkware

Wholesale manufacturing solutions

Contact us to discuss your project requirements.

We support global brands, wholesalers, and promotional companies with factory-direct expertise.