Printing color changing cups is very different from printing normal drinkware.It requires special inks, controlled coating layers, and precise curing processes.

1. What Makes Color Changing Printing Different?

Color changing cups use thermochromic inks that react to temperature.

These inks must be:

Evenly applied

Properly cured

Protected by top coatings

Any mistake affects durability and visual clarity.

2. Main Printing Methods

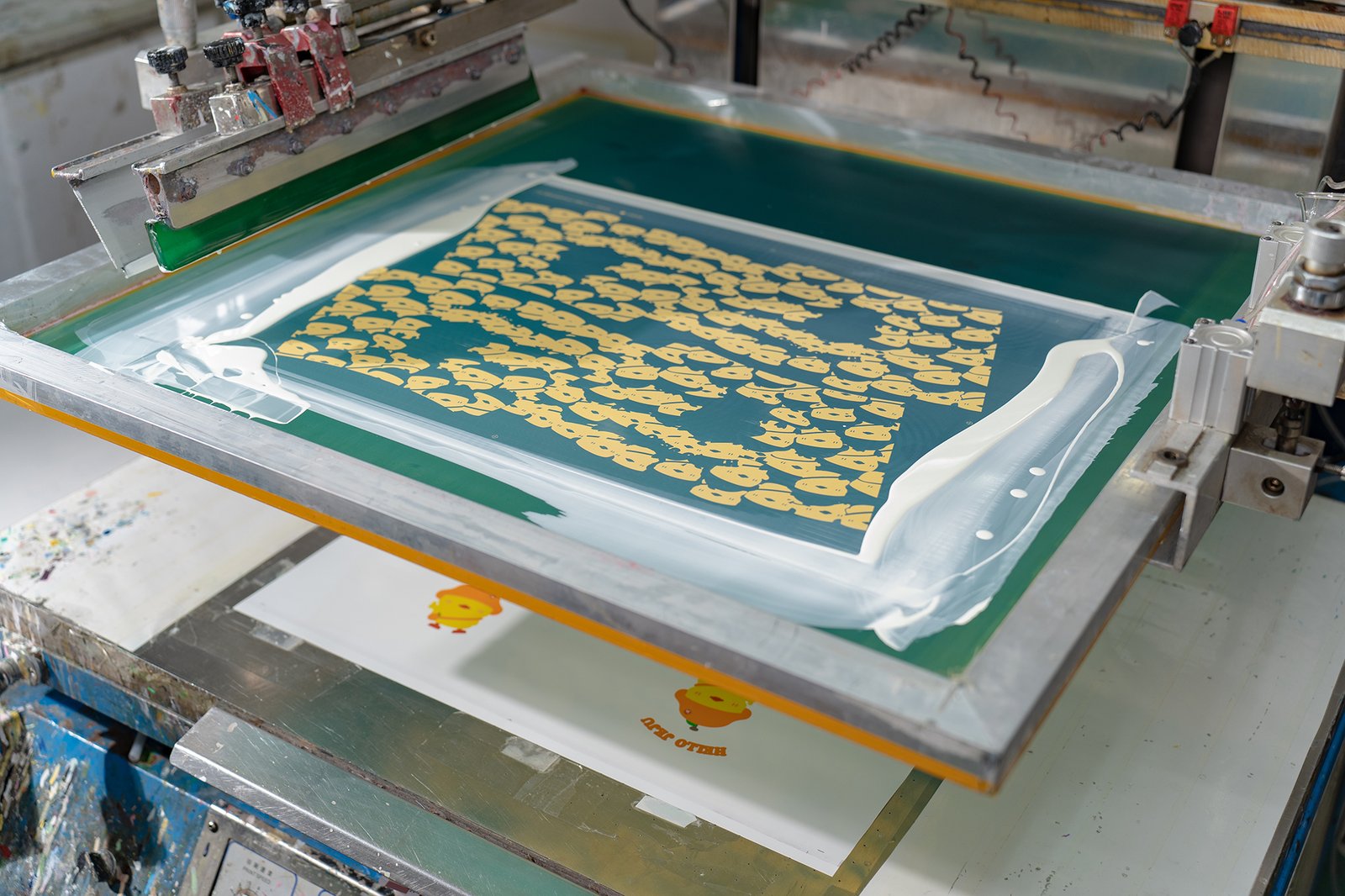

Screen Printing

Best for:

Logos

Simple patterns

Advantages:

Thick ink layer

Strong adhesion

Cost-effective

Heat Transfer Printing

Best for:

Full-wrap designs

Multi-color artwork

Advantages:

High detail

Flexible design

Spray Coating

Best for:

Full-body color changing effects

Advantages:

Smooth surface

Consistent color change

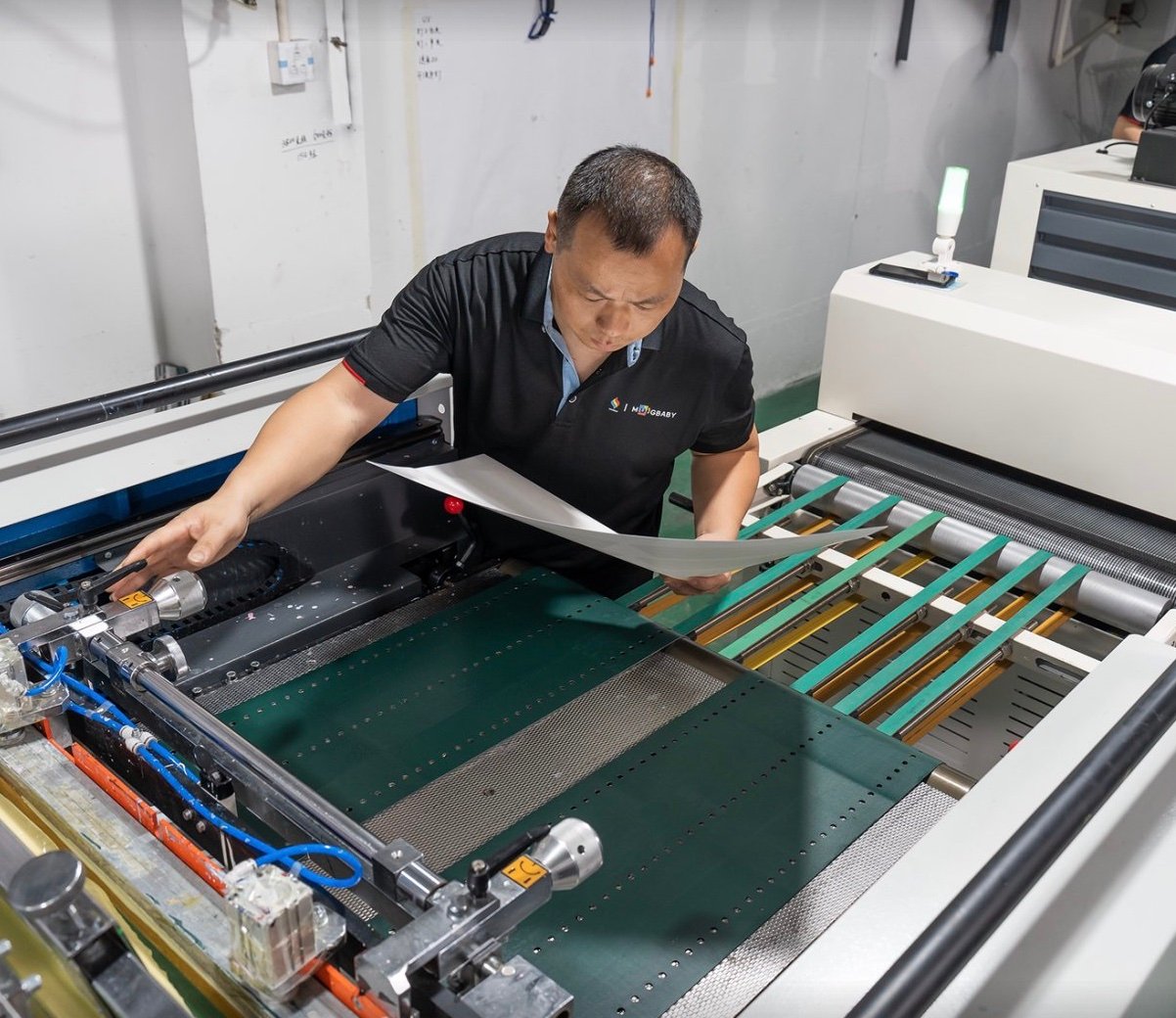

3. Printing Process Overview

Surface preparation

Base coating application

Thermochromic ink printing

Curing & drying

Protective top coating

Quality inspection

4. Curing & Drying Control

Correct curing:

Stabilizes ink

Improves adhesion

Increases lifespan

Over- or under-curing reduces durability.

5. Quality Control Checks

Factories test:

Reaction temperature

Color clarity

Coating thickness

Scratch resistance

6. Common problems and causes of color changing mug printing issues

| Issue | Cause |

|---|---|

| Uneven color | Uneven coating |

| Smearing | Insufficient curing |

| Fading | Low-grade ink |

7. Manufacturer Advice

Printing quality directly determines product lifespan and customer satisfaction.

Looking for Professionally Printed Color Changing Cups?

We provide:

OEM & private label printing

Certified thermochromic inks

Stable batch production

Contact us to request printing samples.