In the color changing mug industry, the biggest risk is not price.

It is inconsistency.

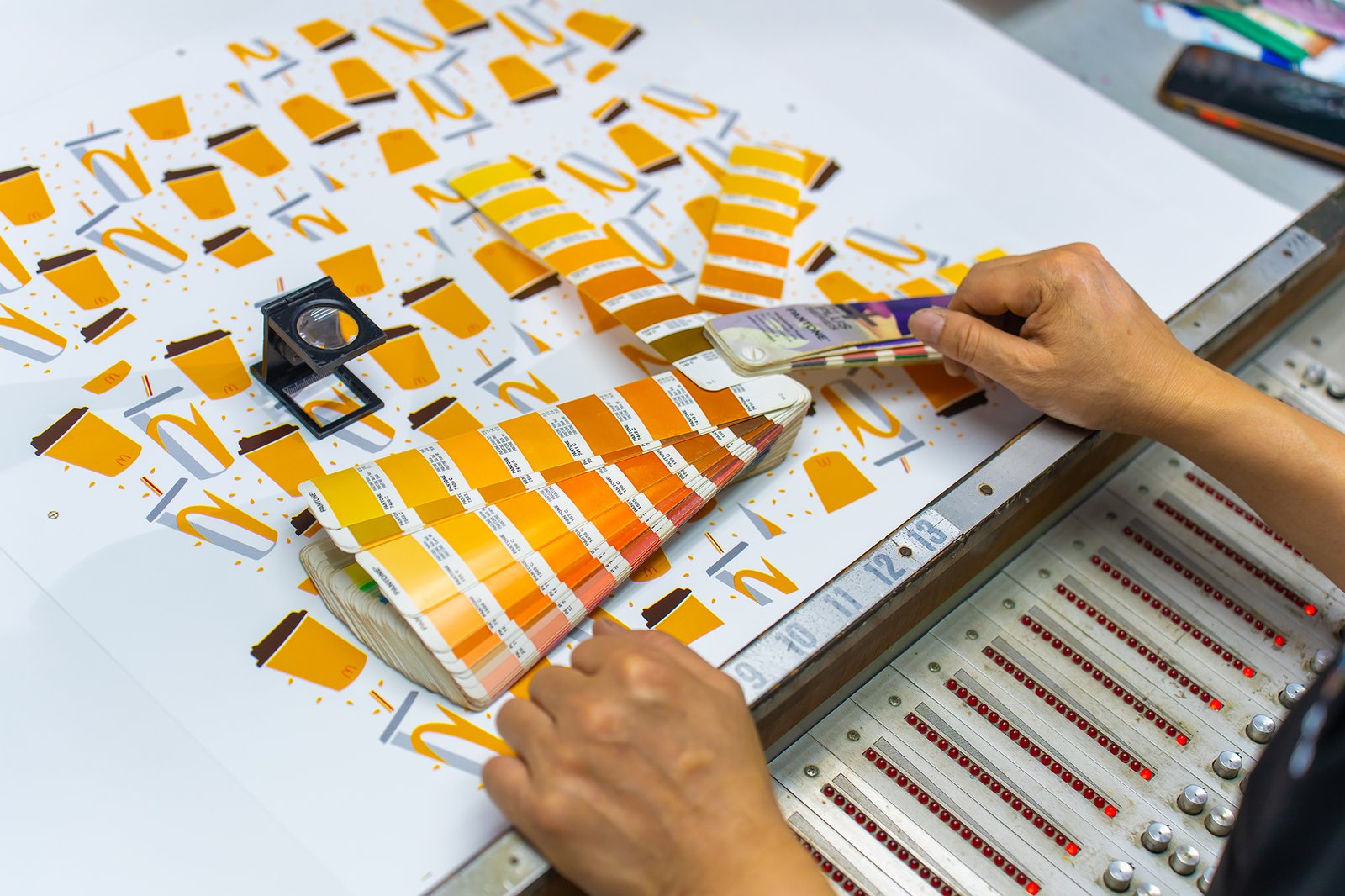

As a heat sensitive mug supplier with in-house coating, printing, and inspection systems, we understand that global brands are not simply buying mugs — they are buying stability, repeatability, and reputation protection.

Every mug must react the same way. Every batch must feel identical.

That is what separates a real manufacturer from a reseller.

What Makes a True Factory Supplier

| Factory-Controlled Stage | Why It Matters |

|---|---|

| Thermochromic coating formulation | Stable color change temperature |

| Automated spray coating | Even surface reaction |

| Multi-layer curing ovens | Long-term durability |

| Precision printing lines | Sharp graphic reveal |

| Internal QC inspection | Lower defect rate |

We manage reaction temperature, fade speed, and recovery time — not just decoration.

Designed for Brand Programs, Not One-Time Orders

We support:

OEM and private label lines

Corporate gift collections

Retail shelf programs

Subscription box supplies

Holiday and seasonal campaigns

Café merchandise programs

Material Options

Ceramic heat sensitive mugs

Glass color changing cups

Reusable plastic magic cups

All materials meet FDA / LFGB / Prop65 food safety compliance.

Production Flow

Thermal reaction engineering

Visual proof and sampling

Pilot production

Mass production (7–12 days)

Batch QC & export shipping

Why Global Buyers Choose Factory Suppliers

Stable re-order consistency

Predictable lead times

Lower long-term cost

Exclusive mold & artwork ownership

Production accountability

Heat sensitive mugs are interactive products.

Interactive products demand engineering — not just printing.

That’s why factory-controlled suppliers outperform resellers in long-term brand growth.