One of the most common questions buyers ask is:How much do custom color changing cups cost?

The answer depends on multiple production factors — not just quantity.

This article explains how manufacturers calculate pricing and how buyers can control cost while maintaining quality.

1. Why Color Changing Cups Are Priced Differently

Unlike ordinary cups, color changing cups include:

Thermochromic ink

Special coating layers

Controlled curing processes

Additional quality inspection

These steps directly affect cost.

2. Main Pricing Factors

| Factor | Impact on Cost |

|---|---|

| Cup material | Plastic < Ceramic < Glass < Metal |

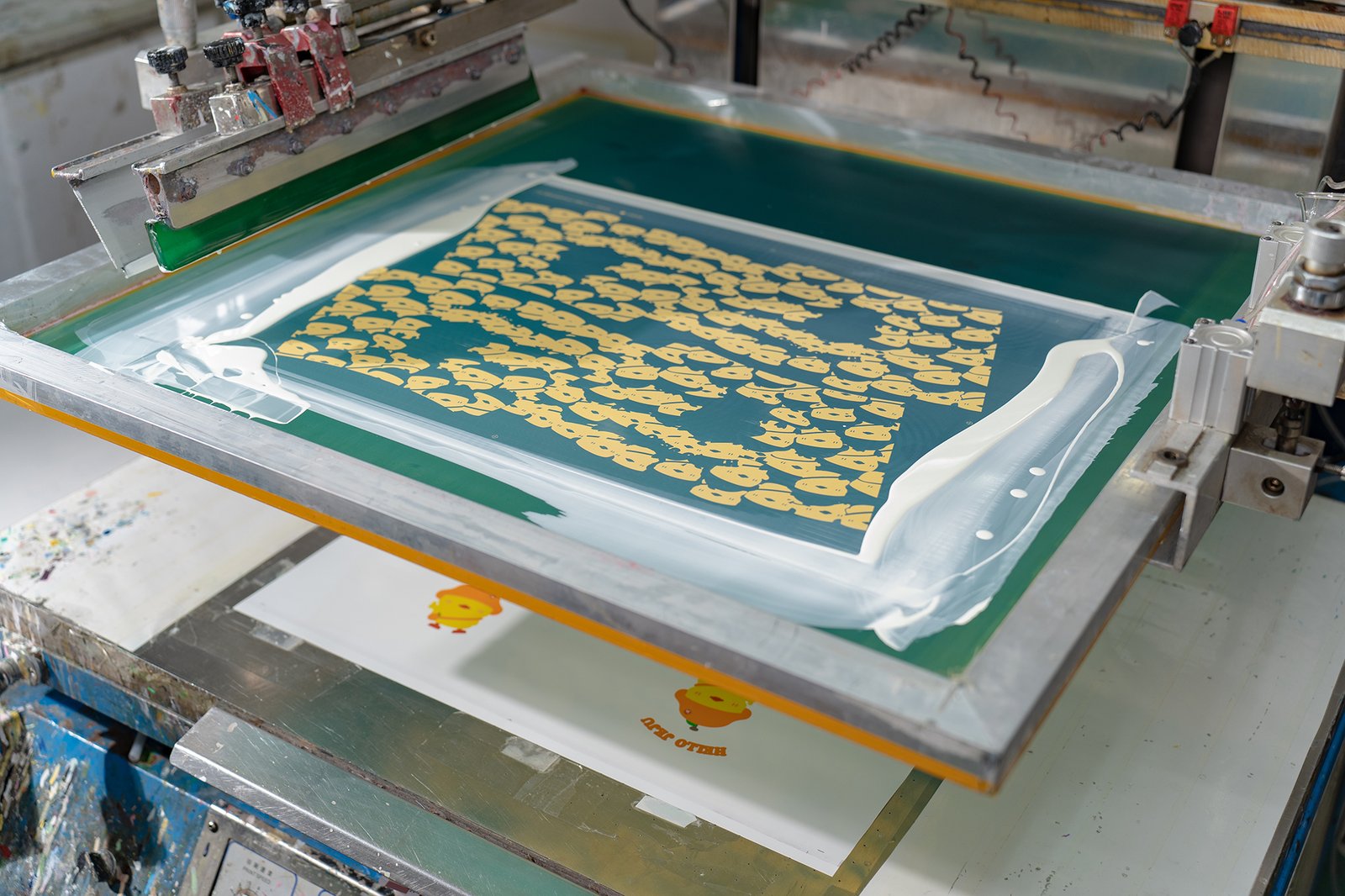

| Printing method | Screen print < Heat transfer < Full wrap |

| Color changing complexity | Reveal effects cost more |

| Order quantity | Higher quantity = lower unit cost |

| Packaging | Custom boxes increase cost |

3. Typical Wholesale Price Ranges

| Factor | Impact on Cost |

|---|---|

| Cup material | Plastic < Ceramic < Glass < Metal |

| Printing method | Screen print < Heat transfer < Full wrap |

| Color changing complexity | Reveal effects cost more |

| Order quantity | Higher quantity = lower unit cost |

| Packaging | Custom boxes increase cost |

4. How to Reduce Cost Without Lowering Quality

Use standard cup molds

Simplify artwork layers

Choose standard packaging

Increase order volume

5. Hidden Cost Risks

Very low prices often mean:

Thinner coating layers

Lower-grade ink

Reduced curing time

These reduce lifespan.

6. Quotation Process

Professional manufacturers provide:

Clear cost breakdown

Sample approval before mass production

Transparent lead time

7. Final Advice

The best pricing balances cost, quality, and long-term performance — not just the cheapest number.

Request a Wholesale Quotation

We offer:

OEM & private label production

Factory-direct pricing

Flexible MOQ solutions

Contact us for detailed pricing.