Thermochromic technology has revolutionized the promotional products industry, turning everyday coffee mugs into interactive brand experiences. As a specialized thermochromic mug factory, we sit at the intersection of material science and ceramic artistry. Our mission is to provide global B2B clients with heat-sensitive drinkware that is not only visually stunning but also meets the highest standards of industrial durability.

What Defines the Tech Behind Our Thermochromic Mugs?

Unlike standard novelty manufacturers, our factory utilizes high-stability thermochromic liquid crystal (TLC) and leuco dye technologies. This ensures that the transition between states is crisp, repeatable, and vibrant.

Advanced Pigment Science

The “magic” happens through a reversible chemical reaction. When hot liquid ($>45^{\circ}C$) enters the vessel, the molecular structure of our coating shifts from opaque to transparent. As a dedicated thermochromic mug factory, we control this sensitivity to ensure:

Uniform Color Change: No patchy transitions; the color shifts smoothly across the entire printed surface.

UV Resistance: Our advanced coatings are engineered to resist fading, extending the lifespan of the color-changing effect.

Compliance-First Manufacturing

Safety is non-negotiable in the food-contact industry. Our production facility is strictly monitored to ensure every batch is:

100% Lead and Cadmium Free: Meeting all FDA, LFGB, and CA Prop 65 requirements.

BPA-Free Coatings: Ensuring that the heat-sensitive layer remains safe for daily human contact.

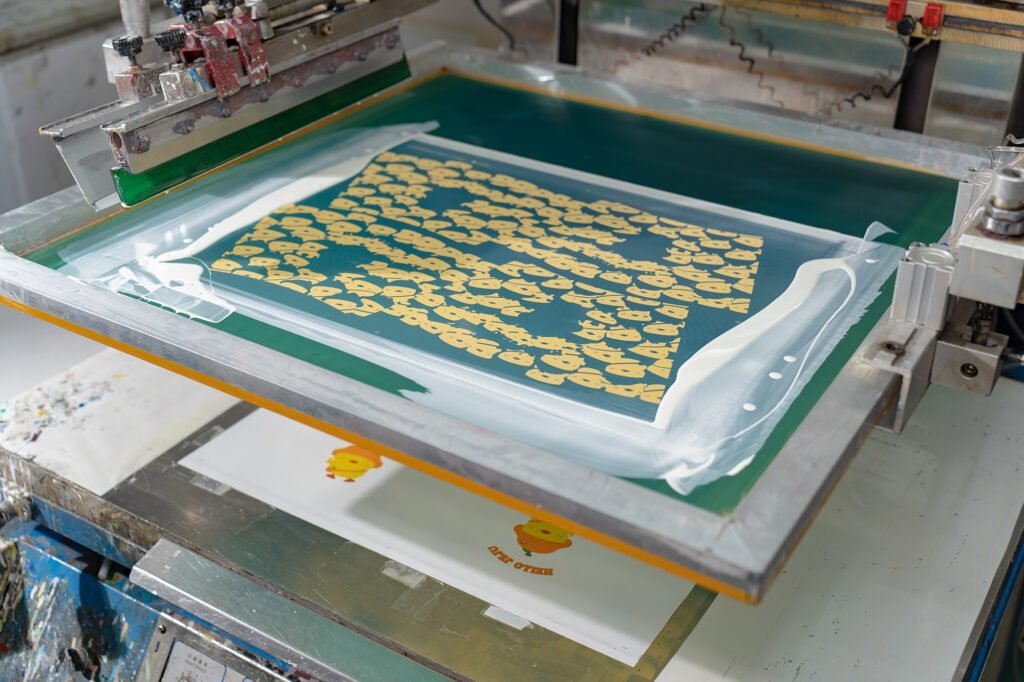

Custom OEM Services for Professional Buyers

Partnering directly with our thermochromic mug factory gives you access to a suite of bespoke manufacturing options:

Hidden Graphic Reveal: The classic “surprise” effect where a logo or photo appears upon heating.

Color-to-Color Transition: Moving from one vibrant hue to another (e.g., from a dark blue background to a bright yellow brand logo).

Matte & Glossy Finishes: We offer specialized tactile coatings that enhance the premium feel of the product.

Ergonomic Ceramic Shapes: Beyond the standard cylinder, we offer heart-shaped handles, cone styles, and travel-ready porcelain.

Our Factory’s Production Capability at a Glance

| Production Aspect | Technical Detail |

| Daily Output Capacity | 25,000+ Units |

| Kiln Temperature | High-fire processing at $1280^{\circ}C$ |

| Printing Accuracy | High-resolution 300+ DPI sublimation |

| Material Sourcing | Grade A Fine Stoneware & Bone China |

Why Global Brands Source Factory-Direct From Us?

When you work with a specialized thermochromic mug factory instead of a middleman, you gain three critical advantages:

Direct Technical Support: Speak directly to our engineers about complex design requirements or specific temperature triggers.

Cost Efficiency: Eliminate markups and enjoy wholesale factory-direct pricing, allowing for higher retail margins.

Quality Traceability: Every mug we produce is batch-tested for transition speed and coating adhesion, ensuring zero defects in your final shipment.

Conclusion: Bring Your Interactive Designs to Life

Whether you are looking to launch a limited-edition retail collection or a large-scale corporate campaign, our thermochromic mug factory is equipped to deliver. We turn your concepts into high-performance, heat-reactive realities that captivate consumers and elevate brands.

Contact our engineering team today for a technical consultation and a free digital prototype!