Thermochromic mugs are not printed products.

They are engineered products.

As a thermochromic mug manufacturer, we do far more than decorate ceramic or glass cups. We control temperature reaction, color recovery speed, and durability — because that is what determines whether a mug becomes a long-term retail product or a short-lived novelty item.

What Thermochromic Manufacturing Really Means

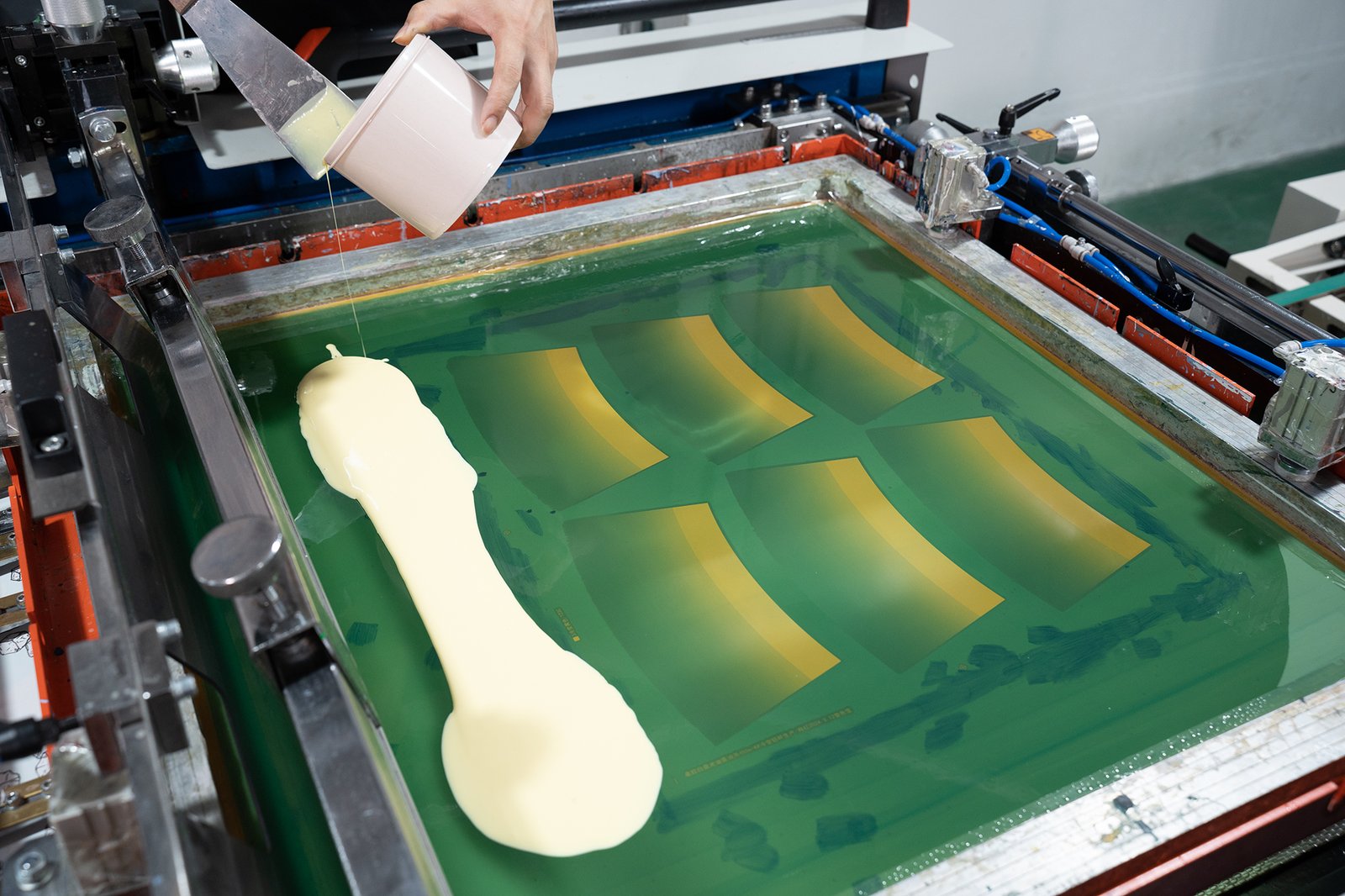

Behind every stable color change is a controlled production system:

| Manufacturing Stage | Why It Matters |

|---|---|

| Pigment formulation | Determines reaction temperature |

| Spray coating uniformity | Ensures smooth reveal |

| Layer curing cycles | Protects long-term performance |

| Graphic encapsulation | Prevents fade & cracking |

| Thermal cycling tests | Simulates years of use |

Designed for Scalable Brand Programs

We manufacture thermochromic mugs for:

Retail shelf programs

Private label gift brands

Café merchandise collections

Corporate gifting lines

Holiday seasonal campaigns

Material Options

Ceramic thermochromic mugs

Glass color changing cups

Plastic reusable magic cups

All materials meet FDA, LFGB, Prop65 and global export compliance.

Factory Production Flow

Reaction engineering

Artwork & sampling

Pilot production

Mass production (7–12 days)

Batch QC & export shipping

Why Global Buyers Choose Factory Manufacturers

Stable reorders

Exclusive molds

Predictable quality

Lower long-term cost

Reliable supply chain

Final Thought

Thermochromic mugs succeed not because they change color —

but because they change color reliably, every time.

Engineering is the difference between novelty and brand product.