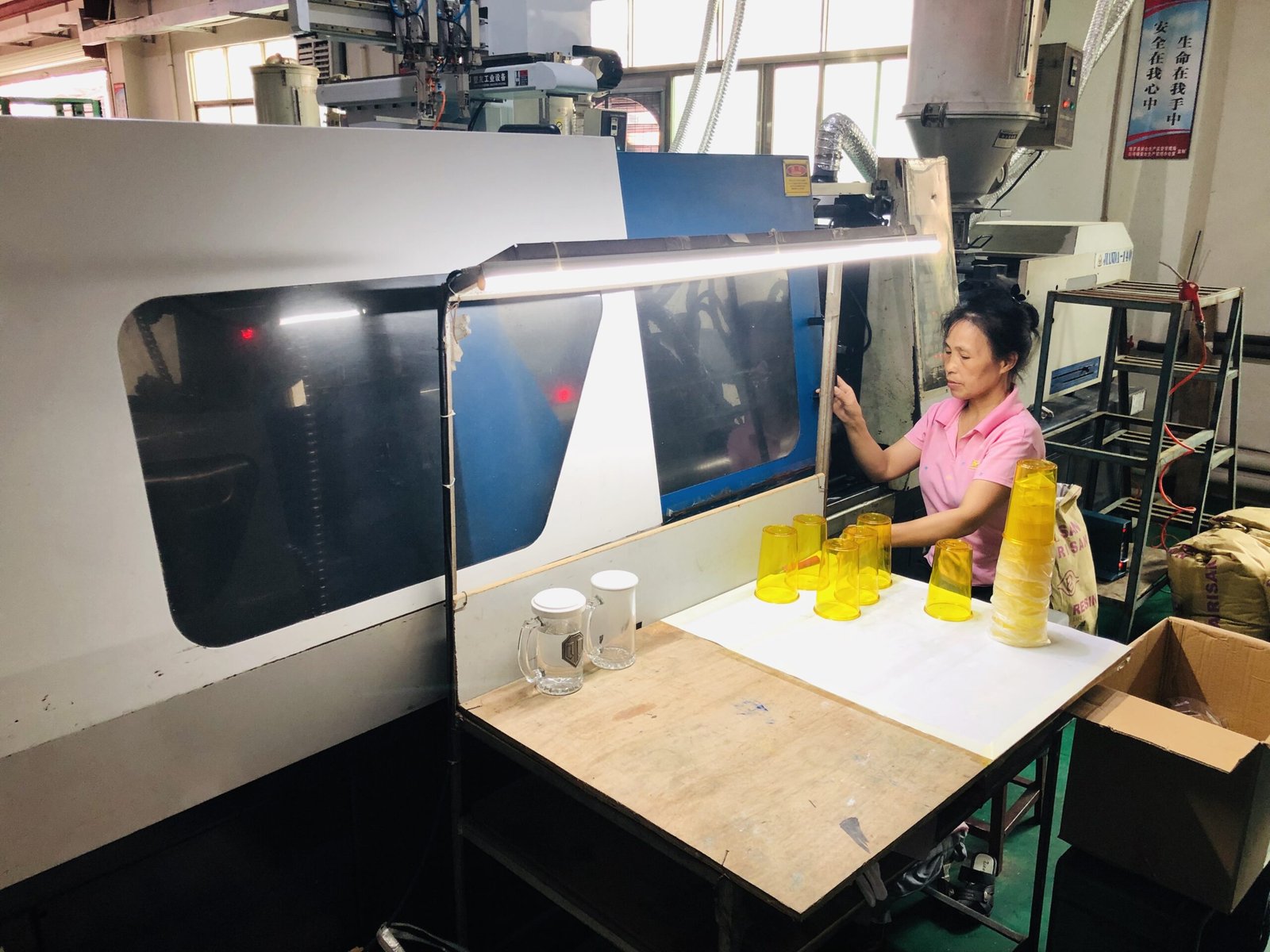

When sourcing custom color changing cups, MOQ is one of the first and most important questions buyers ask.

As a professional color changing cup manufacturer, this guide explains how MOQ works and how buyers can choose the most suitable quantity.

1. What Does MOQ Mean?

MOQ (Minimum Order Quantity) is the lowest quantity a factory can produce while maintaining stable quality and reasonable cost.

For color changing cups, MOQ covers:

Ink preparation

Printing setup

Coating and curing

Quality inspection

2. Typical MOQ by Cup Type

| Cup Type | Typical MOQ |

|---|---|

| Ceramic color changing mug | 300–500 pcs |

| Glass color changing cup | 500–1000 pcs |

| Plastic color changing cup | 1000–3000 pcs |

| Tumblers with lids | 1000+ pcs |

MOQ varies based on design complexity.

3. Why MOQ Cannot Be Too Low

Low MOQ increases:

Ink waste

Setup cost

Unit price

Quality risks

Factories use MOQ to balance cost and stability.

4. What Factors Influence MOQ?

| Factor | Impact |

|---|---|

| Printing complexity | Higher complexity = higher MOQ |

| Cup material | Plastic usually requires higher MOQ |

| Custom packaging | Increases MOQ |

| Special color changing effects | Increase MOQ |

5. Can MOQ Be Lowered?

In some cases:

Using stock cup shapes

Simple artwork

Standard packaging

Factories may accept trial MOQ.

6. MOQ vs Unit Price Relationship

Lower MOQ = Higher unit price

Higher MOQ = Lower unit price

MOQ helps buyers optimize cost efficiency.

7. Wholesale Buyer Tips

Confirm final design before quoting

Avoid unnecessary customization

Choose stock molds

Plan for long-term supply

8. Common MOQ Mistakes

Trying to push MOQ too low

Comparing MOQs without checking product specs

Ignoring quality control cost

9. Final Advice

The right MOQ is the one that ensures stable quality, safe performance, and acceptable unit cost — not simply the lowest number.

Looking for Wholesale MOQ Options?

We offer:

Flexible MOQ for stock designs

Custom OEM projects

Factory-direct wholesale pricing

Contact us for MOQ and quotation.