Color changing cups are designed to create a strong visual impact, but over time some buyers notice that the color-changing effect becomes weaker.

This leads to a common B2B question:

Why do color changing cups fade over time?

As a professional color changing cup manufacturer, we will explain the real reasons behind fading, what is considered normal, and how buyers can reduce fading risks through correct product specifications.

1. First: Is Fading a Defect?

Not always.

Color changing cups use thermochromic pigments, which are functional materials that naturally degrade gradually with repeated use.

From a manufacturing perspective:

Gradual fading is a normal aging process, not an immediate quality defect.

The key issue is how fast the fading happens.

2. The Nature of Thermochromic Pigments

Thermochromic pigments work through reversible molecular changes triggered by temperature.

Each heat cycle:

Alters the internal structure slightly

Causes minor molecular fatigue

Over time, these micro-level changes accumulate, leading to:

Reduced color contrast

Slower reaction speed

This is inherent to the technology, not a manufacturing mistake.

3. Repeated Heat Activation Is the Main Cause

Every time a hot drink is poured into the cup, the color changing layer is activated.

High-frequency use leads to:

Faster pigment fatigue

Accelerated color loss

Cups used daily will fade faster than:

Promotional mugs used occasionally

Display or gift items

This is why usage scenario matters in B2B projects.

4. Activation Temperature Settings Matter

Lower activation temperatures increase fading speed.

Why?

Lower thresholds cause more frequent activation

Even warm water can trigger the effect

Pigments stay in an “active” state longer

From a factory viewpoint:

Overly sensitive ink sacrifices lifespan for faster reaction.

That is why experienced manufacturers avoid extremely low activation settings.

5. Dishwashers: The Biggest Enemy

Dishwashers combine:

High heat

Strong detergents

Mechanical abrasion

Together, they:

Damage the protective coating

Break down pigment microcapsules

Accelerate fading dramatically

Many “quality complaints” are actually usage-related, not production defects.

6. UV Light and Sun Exposure

Long-term exposure to sunlight can:

Break down pigment stability

Cause uneven fading

Reduce contrast

This is especially relevant for:

Plastic color changing cups

Outdoor promotional use

UV resistance varies by ink formulation and coating quality.

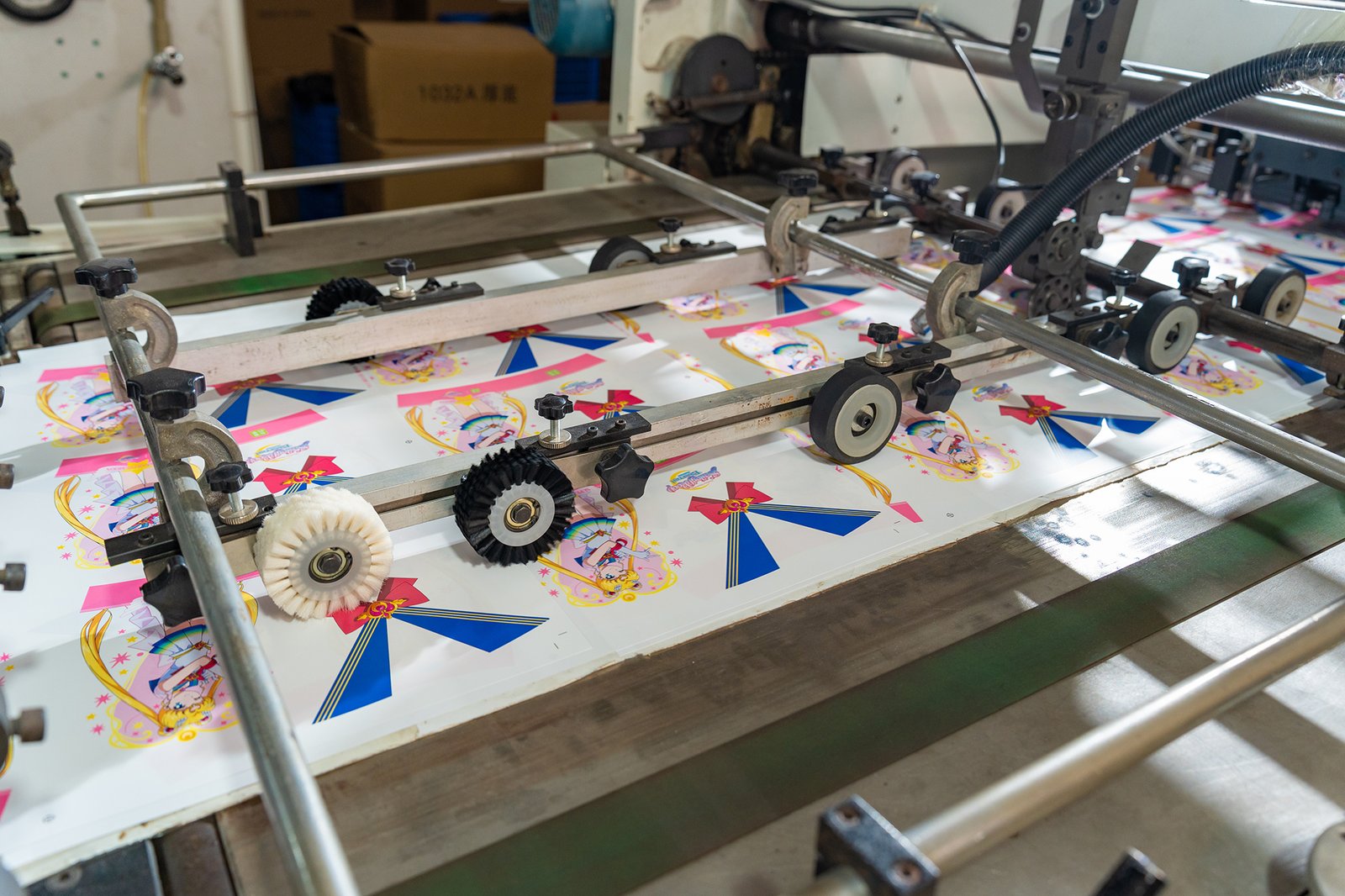

7. Ink Layer Thickness and Protection

Ink that is:

Too thin → fades quickly

Too thick → reacts slowly

Professional factories balance:

Visual effect

Durability

Wash resistance

A proper protective topcoat significantly slows fading.

8. Cup Material Influences Fading Speed

Different materials transfer heat differently:

Ceramic: slow, even heat → slower fading

Glass: faster heat transfer → moderate fading

Plastic: quick temperature change → faster fading

This is why ceramic color changing mugs usually last longer.

9. Common Buyer Misunderstandings

“Fading means the product is fake”

Incorrect — fading happens even with high-quality ink.

“All fading is caused by poor factories”

Not true — usage conditions play a major role.

“Higher temperature means better durability”

Wrong — extreme heat accelerates degradation.

10. How Manufacturers Reduce Fading

Professional manufacturers take multiple measures:

Use stable thermochromic pigments

Optimize activation temperature

Apply protective coatings

Control curing processes

Conduct cycle testing

These steps slow fading, but cannot eliminate it completely.

11. What Buyers Can Do to Minimize Fading

For B2B buyers and brands, fading risk can be reduced by:

Choosing ceramic over plastic

Avoiding ultra-low activation temperatures

Providing clear usage instructions

Avoiding dishwasher-safe claims

Correct expectation management reduces after-sales issues.

12. Is Fading Avoidable?

Fading is inevitable over a long period, but it can be controlled.

With proper manufacturing and reasonable usage:

Color changing cups remain effective for 1–3 years

Fading is gradual, not sudden

13. Final Words from the Manufacturer

Understanding why color changing cups fade helps buyers:

Choose realistic specifications

Avoid unnecessary disputes

Build better long-term products

A reliable manufacturer focuses on controlled aging, not unrealistic promises.

Need Long-Lasting Color Changing Cups?

If you are sourcing:

Stable thermochromic ink solutions

Factory-direct quality control

Contact us to discuss your project requirements.

We help B2B buyers reduce fading risks through proper design and manufacturing.